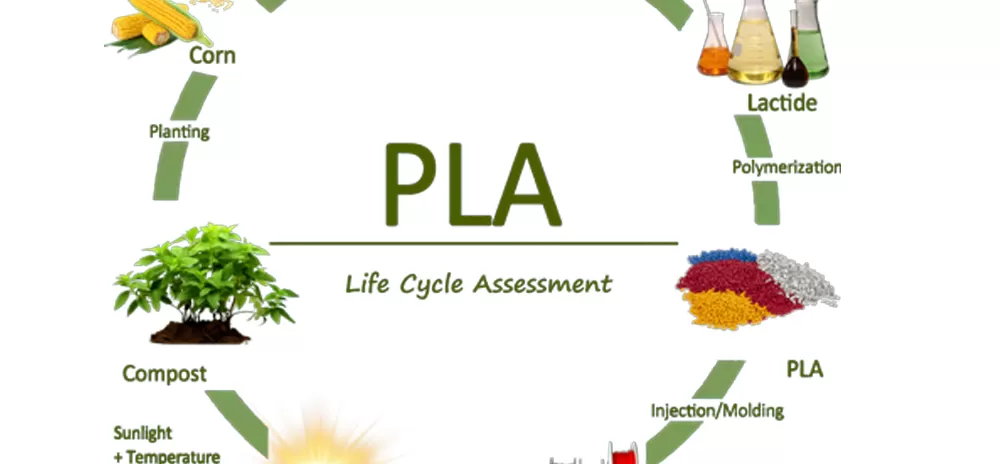

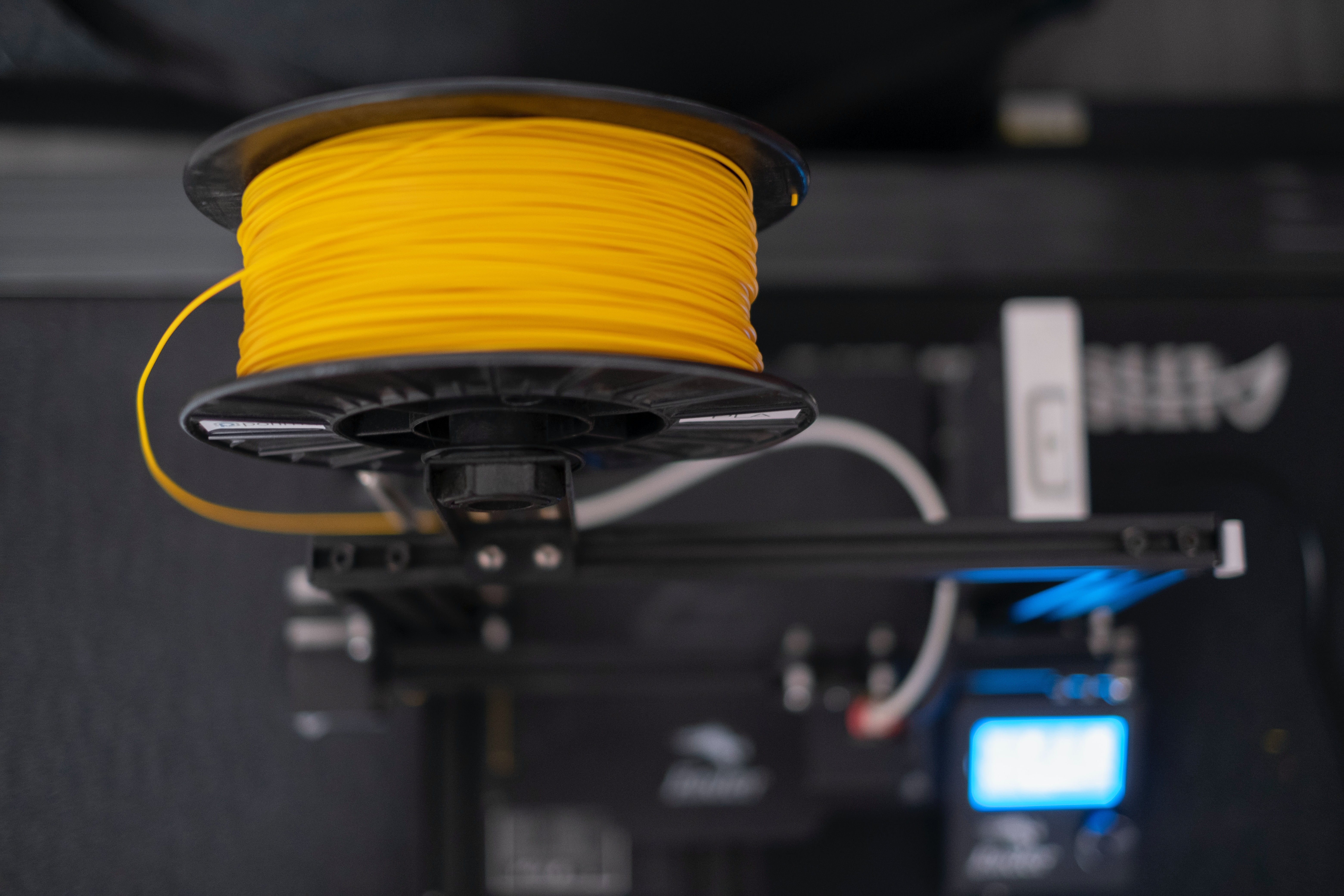

There are many different types of filaments in the world of 3D printing, the two most popular being PLA (polylactide)...

Filament Easy PLA Alien...

dashboard

clear

-

Filament Easy PLA Candy 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Candy 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Black 1,75 mm 2,5kg Fiberlogy

Filament Easy PLA Black 1,75 mm 2,5kg Fiberlogy -

Filament Easy PLA Blue 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Blue 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Brown 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Brown 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Burgundy 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Burgundy 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Graphite 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Graphite 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Gray 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Gray 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Green 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Green 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Inox 1.75mm 0.85kg Fiberlogy

Filament Easy PLA Inox 1.75mm 0.85kg Fiberlogy -

Filament Easy PLA Light Green 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Light Green 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Midnight Sky 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Midnight Sky 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Navy Blue 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Navy Blue 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Old Gold 1.75 mm 0.85kg Fiberlogy

Filament Easy PLA Old Gold 1.75 mm 0.85kg Fiberlogy -

Filament Easy PLA ONYX 1,75 mm 0,85 kg Fiberlogy

Filament Easy PLA ONYX 1,75 mm 0,85 kg Fiberlogy -

Filament Easy PLA Orange 1.75 mm 0.85kg Fiberlogy

Filament Easy PLA Orange 1.75 mm 0.85kg Fiberlogy -

Filament Easy PLA Pastel Blue 1.75 mm 0.85 kg Fiberlogy

Filament Easy PLA Pastel Blue 1.75 mm 0.85 kg Fiberlogy -

Filament Easy PLA Pastel Lilac 1.75 mm 0.85 kg Fiberlogy

Filament Easy PLA Pastel Lilac 1.75 mm 0.85 kg Fiberlogy -

Filament Easy PLA Pastel Mint 1.75 mm 0.85 kg Fiberlogy

Filament Easy PLA Pastel Mint 1.75 mm 0.85 kg Fiberlogy -

Filament Easy PLA Pastel Yellow 1.75 mm 0.85 kg Fiberlogy

Filament Easy PLA Pastel Yellow 1.75 mm 0.85 kg Fiberlogy -

Filament Easy PLA Pink 1.75 mm 0.85kg Fiberlogy

Filament Easy PLA Pink 1.75 mm 0.85kg Fiberlogy -

Filament Easy PLA Red 1,75 mm 0,85 kg Fiberlogy

Filament Easy PLA Red 1,75 mm 0,85 kg Fiberlogy -

Filament Easy PLA Red Orange 1.75 mm 0.85 kg Fiberlogy

Filament Easy PLA Red Orange 1.75 mm 0.85 kg Fiberlogy -

Filament Easy PLA Ruby Red 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Ruby Red 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Spectra Blue 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Spectra Blue 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA True Blue 1,75 mm 0,85 kg Fiberlogy

Filament Easy PLA True Blue 1,75 mm 0,85 kg Fiberlogy -

Filament Easy PLA True Gold 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA True Gold 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA White 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA White 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Yellow 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Yellow 1,75 mm 0,85kg Fiberlogy -

Filament Easy PLA Aurora 1.75 mm 0.85kg Fiberlogy

Filament Easy PLA Aurora 1.75 mm 0.85kg Fiberlogy -

Filament Easy PLA Beige 1.75 mm 0.85kg Fiberlogy

Filament Easy PLA Beige 1.75 mm 0.85kg Fiberlogy -

Filament Easy PLA Vertigo 1.75 mm 0.85kg Fiberlogy

Filament Easy PLA Vertigo 1.75 mm 0.85kg Fiberlogy -

Filament Easy PLA Black 1,75 mm 0,85kg Fiberlogy

Filament Easy PLA Black 1,75 mm 0,85kg Fiberlogy

zł88.40

zł104.00

-15%

- -15%

Zostaw komentarz